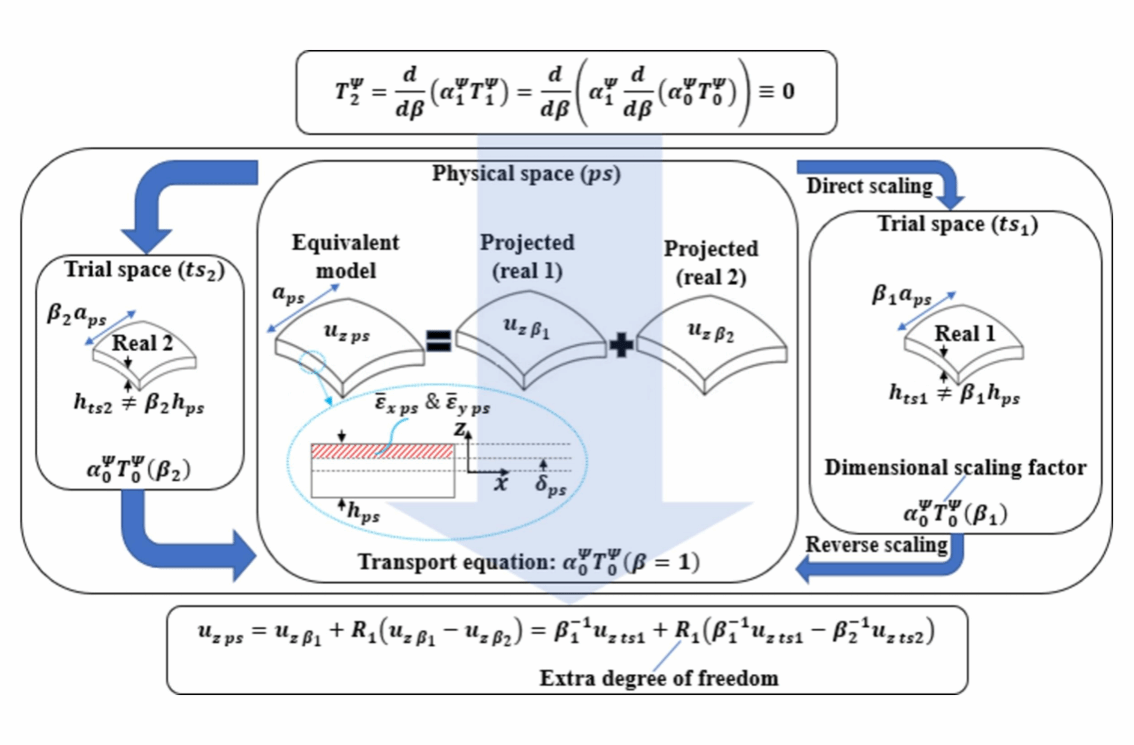

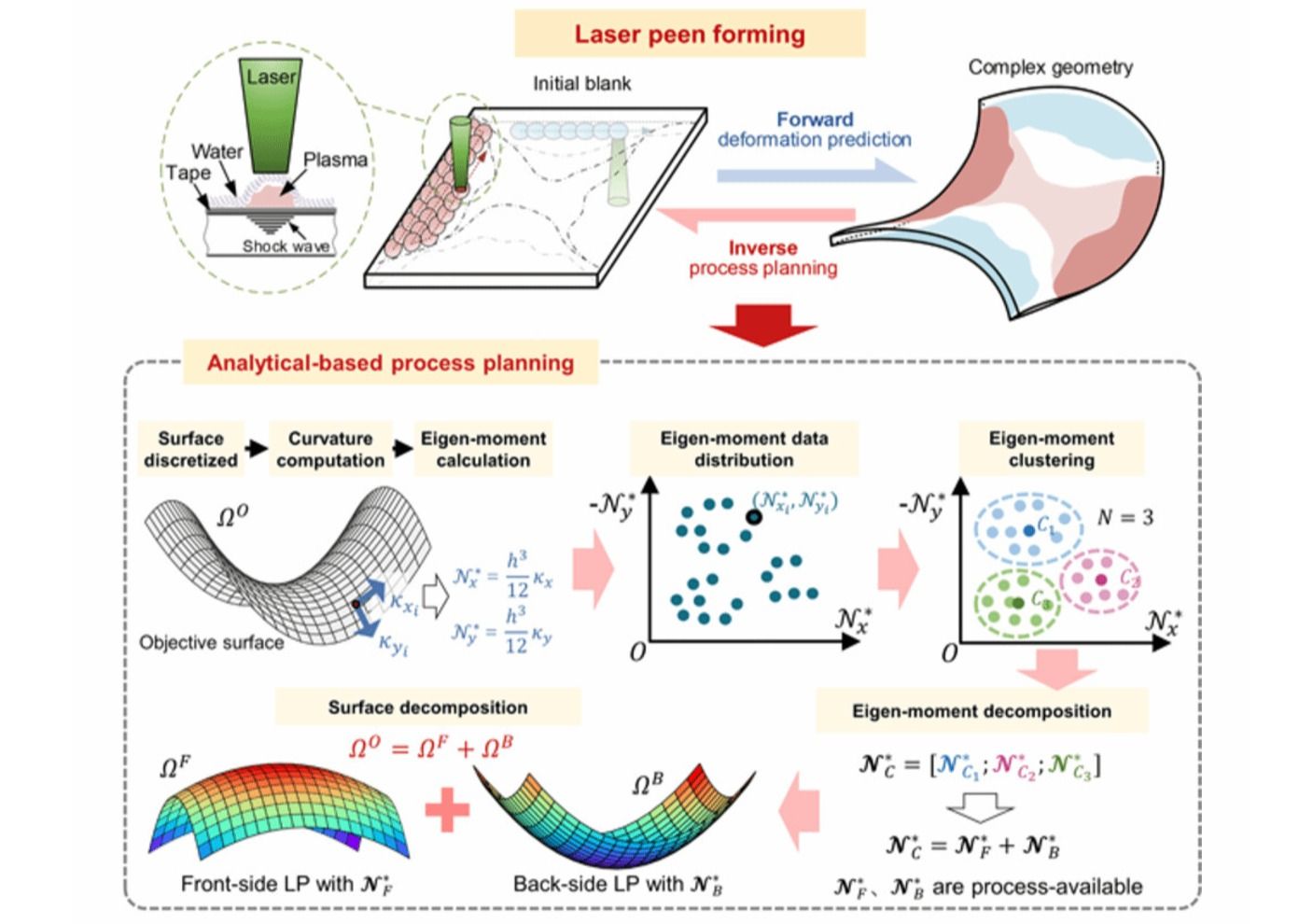

Bifurcation-dominated nonlinear bending behavior of laser peen forming: Analytical modeling and energy competition mechanism

Dr. Jiang identified LPF nonlinear deformation as bifurcation-dominated bending from geometric nonlinearity-governed mismatch strain. An eigenstrain model was developed, with Al alloy experiments validating bifurcation and morphological transitions. Analyses clarified plate dimension/energy effects, derived a criterion and built a shape morphing design theoretical framework. This work was recently published in J MATER PROCESS TECH

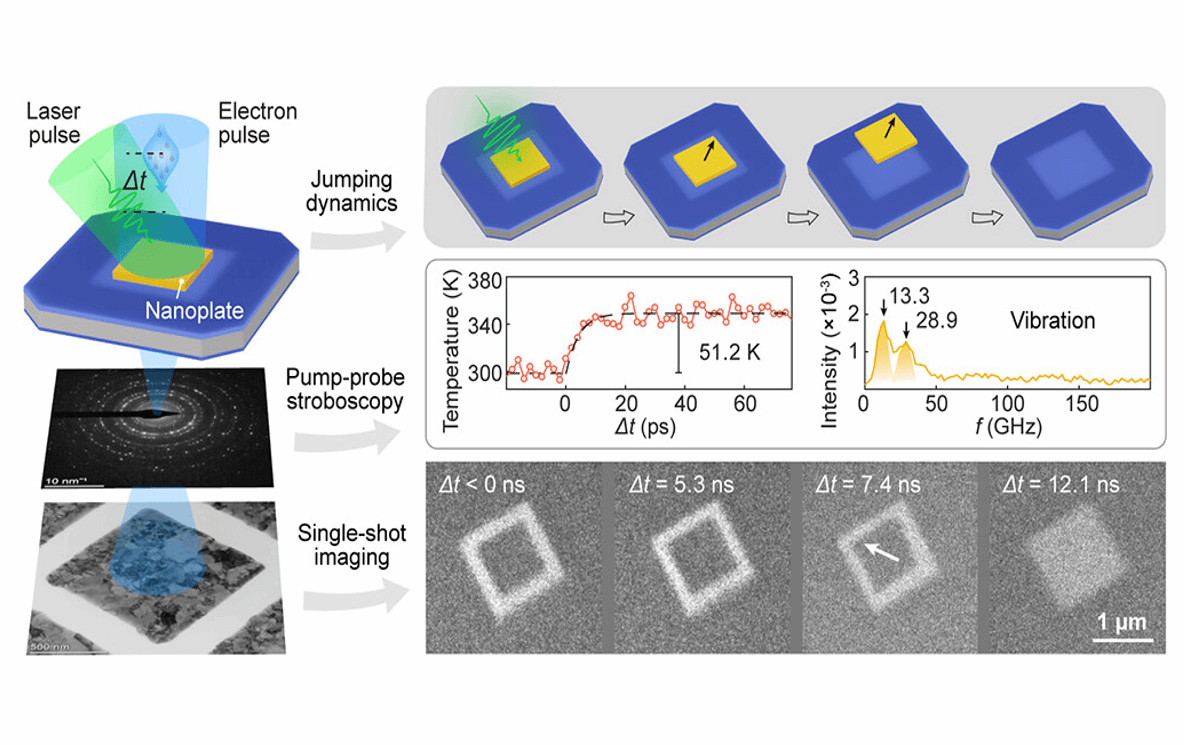

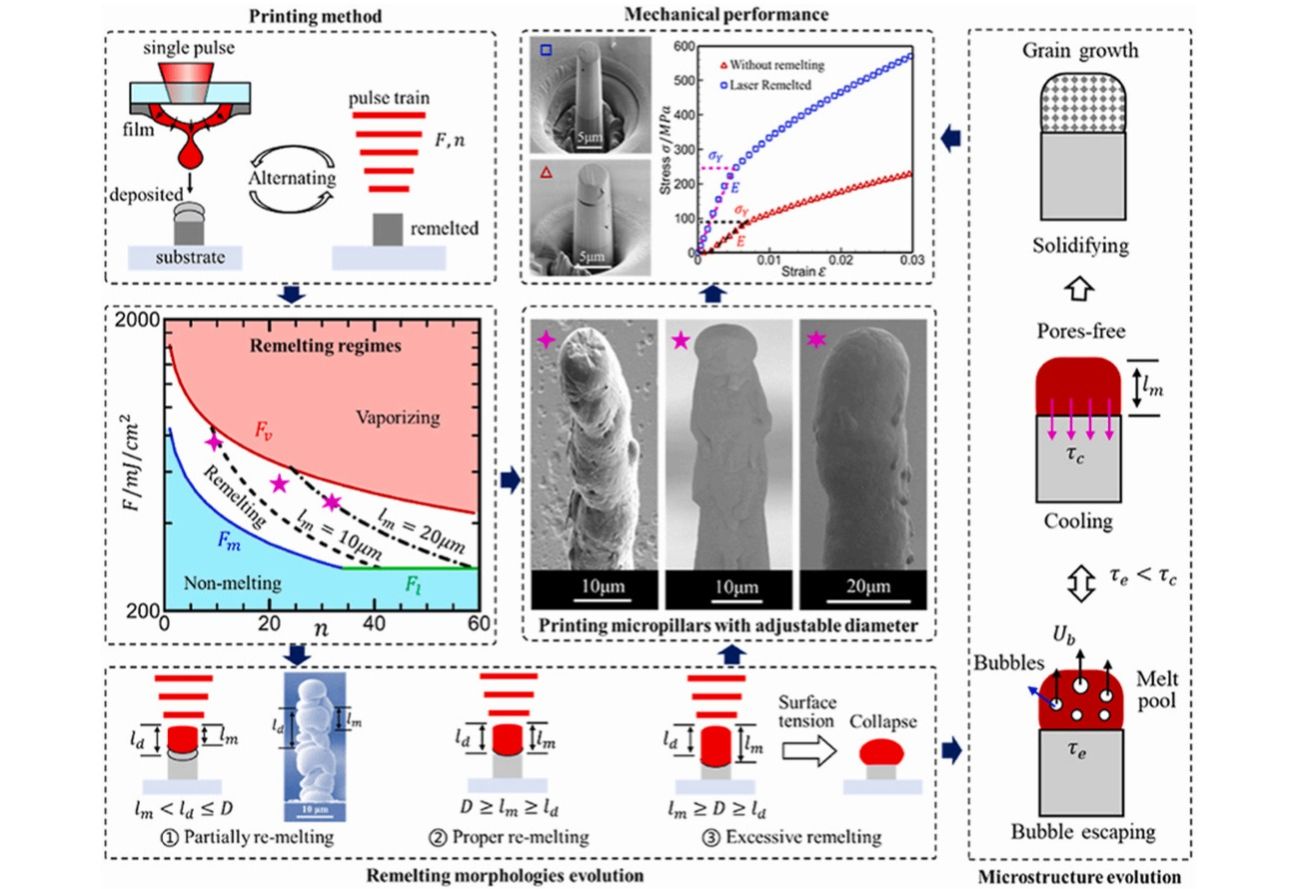

Thermal stress wave-driven regime in femtosecond laser-induced nanomaterial transfer revealed by ultrafast electron microscopy and atomic simulation

Dr. Zhou integrated pulsed lasers with TEM to observe nanoisland nanoscale transfer. Combining two-temperature modeling and molecular dynamics simulations, it revealed a novel thermal stress wave-driven transfer regime, with nanoislands detaching in tens of picoseconds and melting in nanoseconds—first confirmed by experiment and simulation. This work was recently published in INT J MACH TOOL MANU

Spatiotemporal visualization of nanoscale rotational dynamics by movie-mode transmission electron microscopy

Dr. Zhou employed movie-mode transmission electron microscopy to investigate the rotational dynamics of laser-excited nanotriangles. It revealed axis-dependent rotation stability consistent with the tennis racket effect, validating classical rigid-body rotational theory at this scale, and quantifying nanotriangle-substrate adhesion to advance understanding of nanoscale rotational dynamics. This work was recently published in ACS NANO

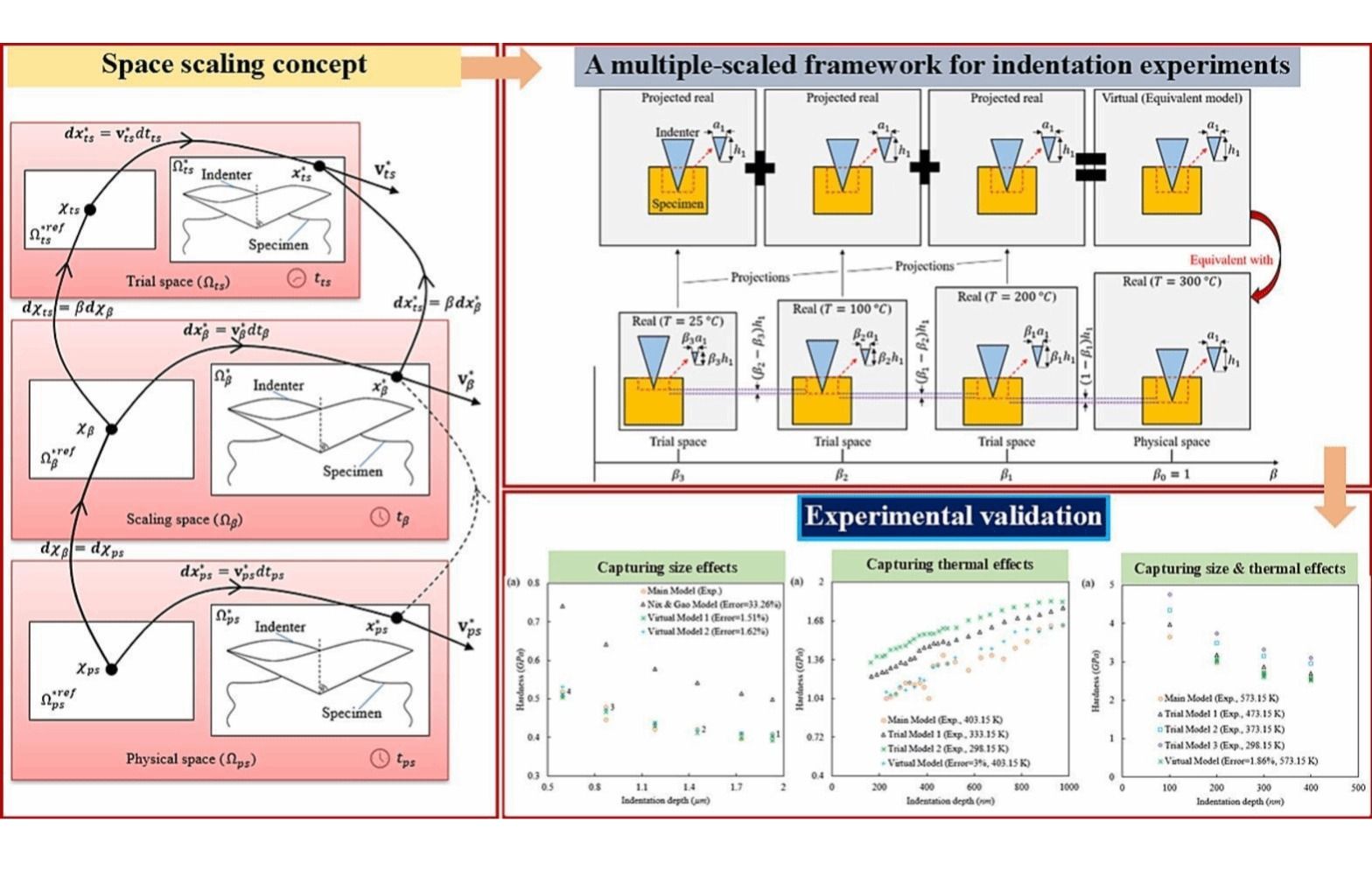

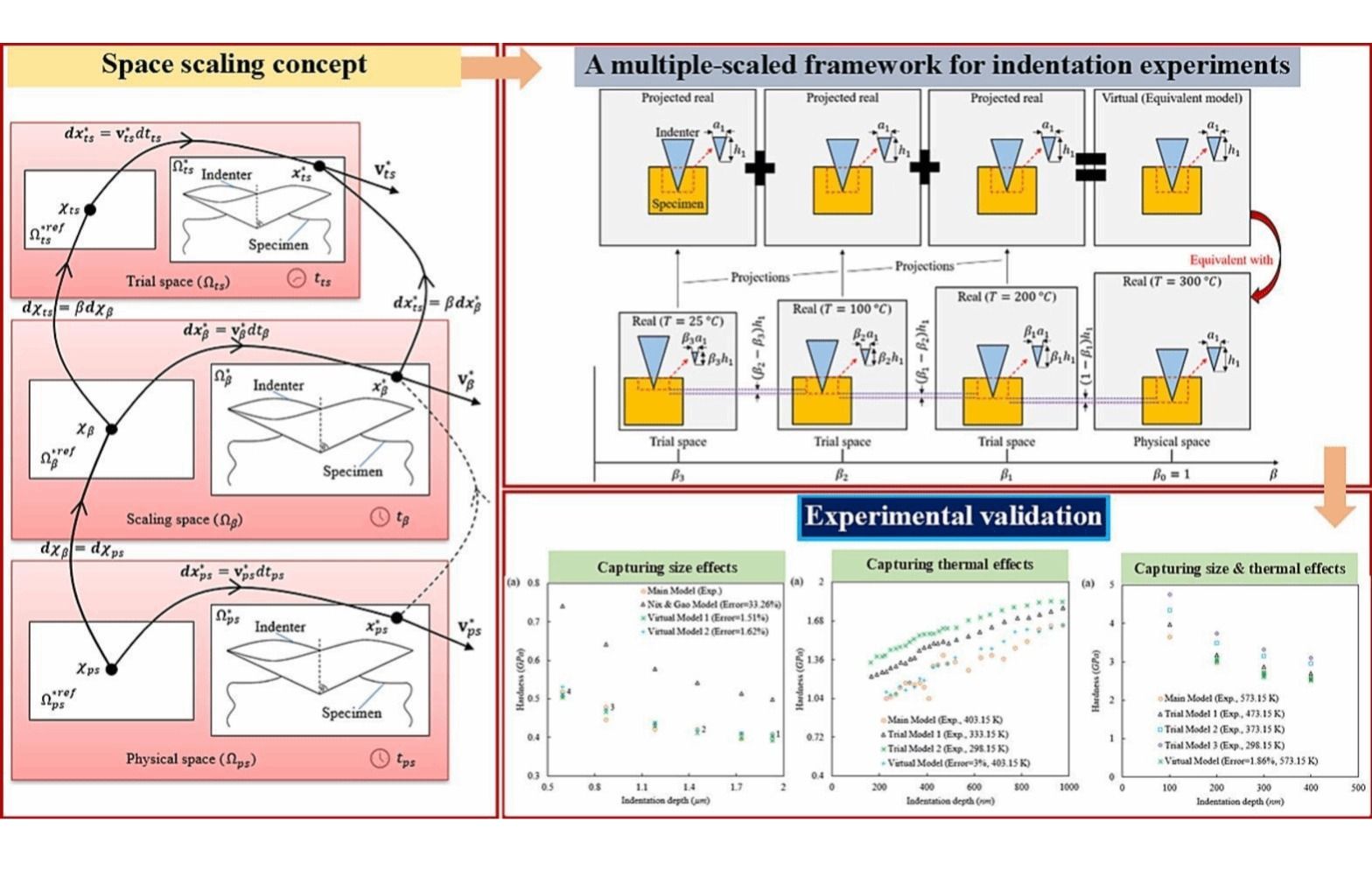

Indentation size effects: A study via finite similitude scaling theory

Dr. Hamed developed a multiscaled approach for indentation experiments using finite-similitude scaling theory. This methodology can capture indentation size effects and enable high-temperature analysis. Simulations and experiments showed that similitude correction can achieve high accuracy in hardness recovery for crystalline materials, with errors mostly under 9%. This work was recently published in MATER DESIGN.

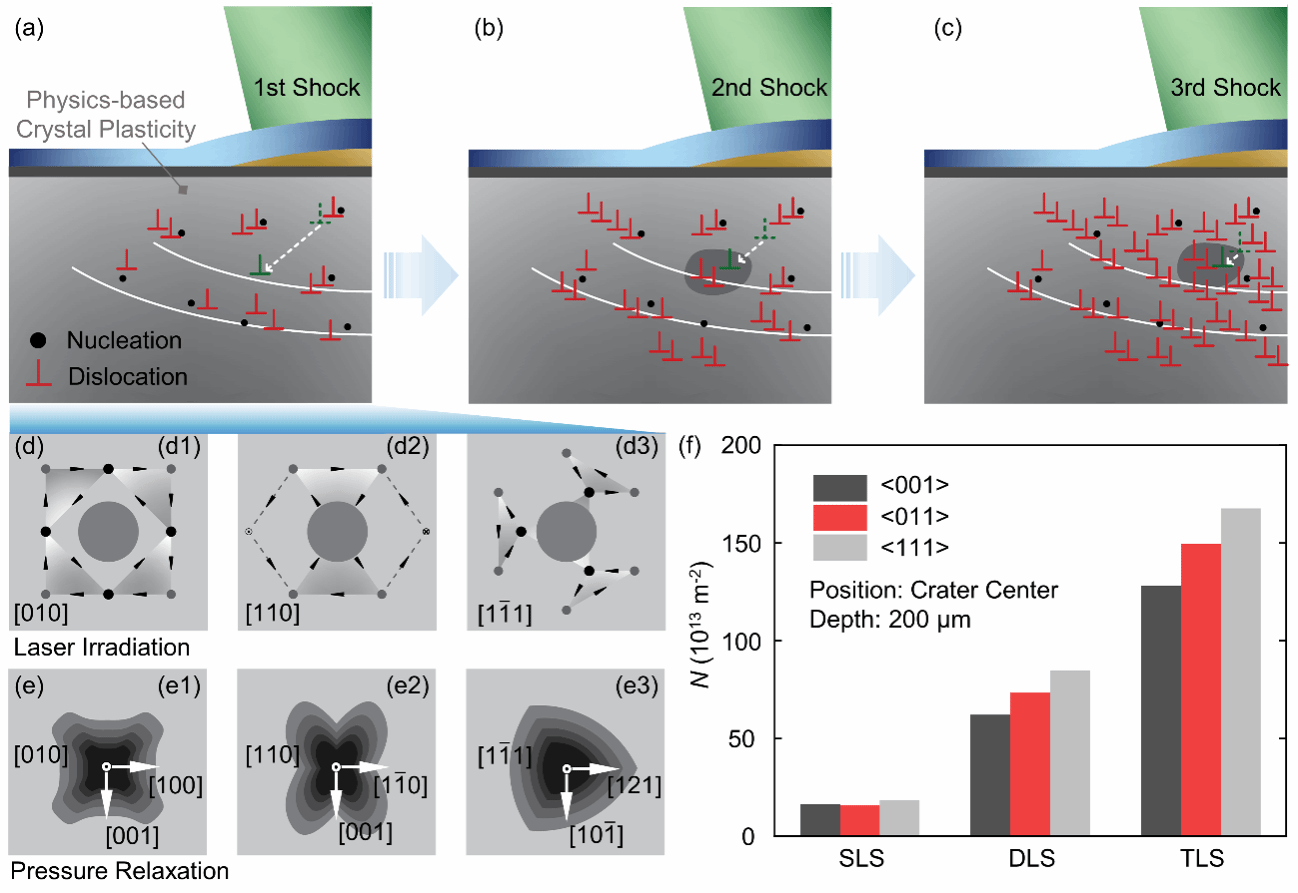

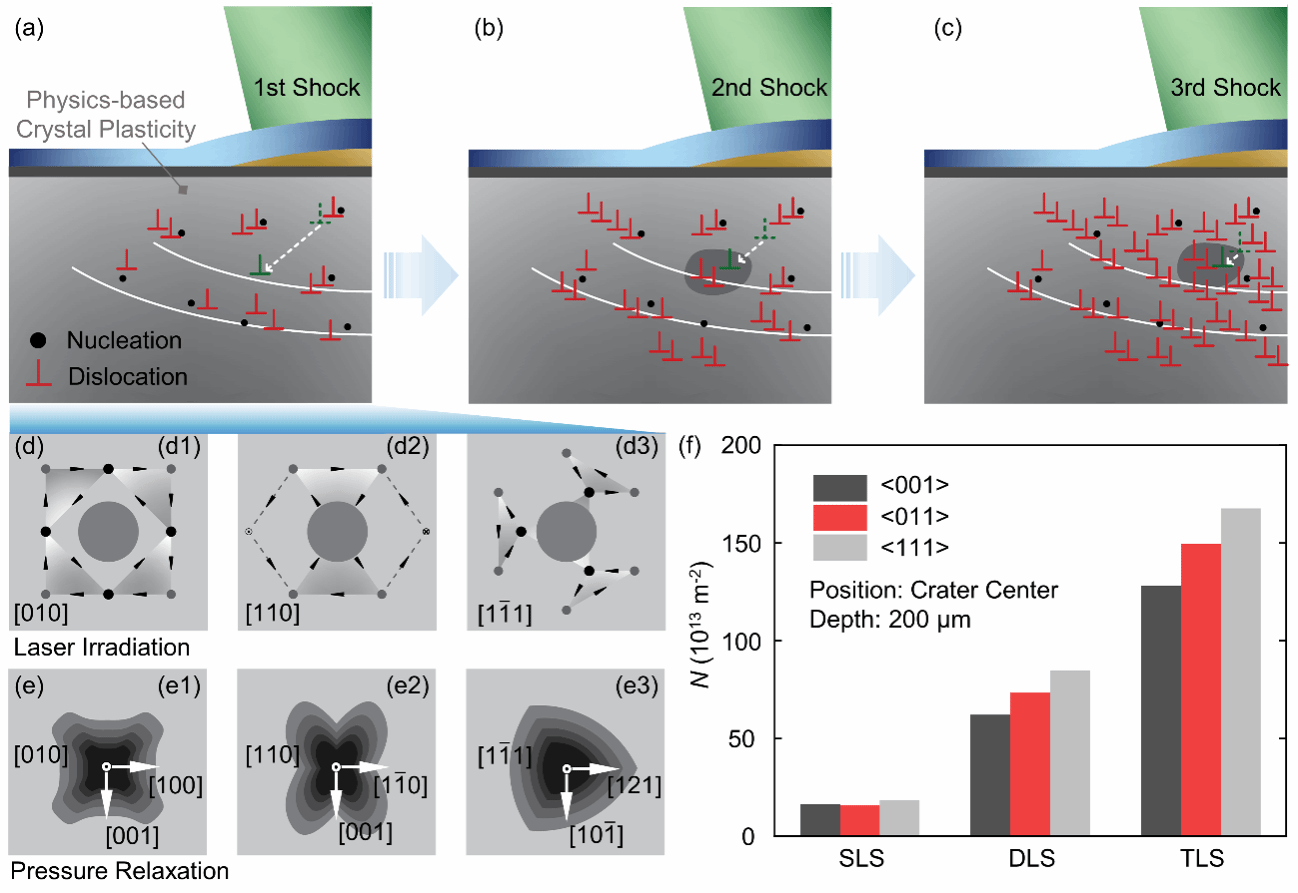

Dynamic dislocation response in aluminum single crystals under multiple laser peening: A physics-based crystal plasticity study

Ph.D. student Siyuan Chen simulated the dislocation response of aluminum single crystals under laser peening based on a crystal plasticity finite element (CPFE) model. The results indicate that dislocation patterns are axisymmetric during laser irradiation due to the ultra-high slip velocity. Phonon drag induced additional strength during the first shock for the low dislocation density. This work was recently published in INT J PLASTICITY

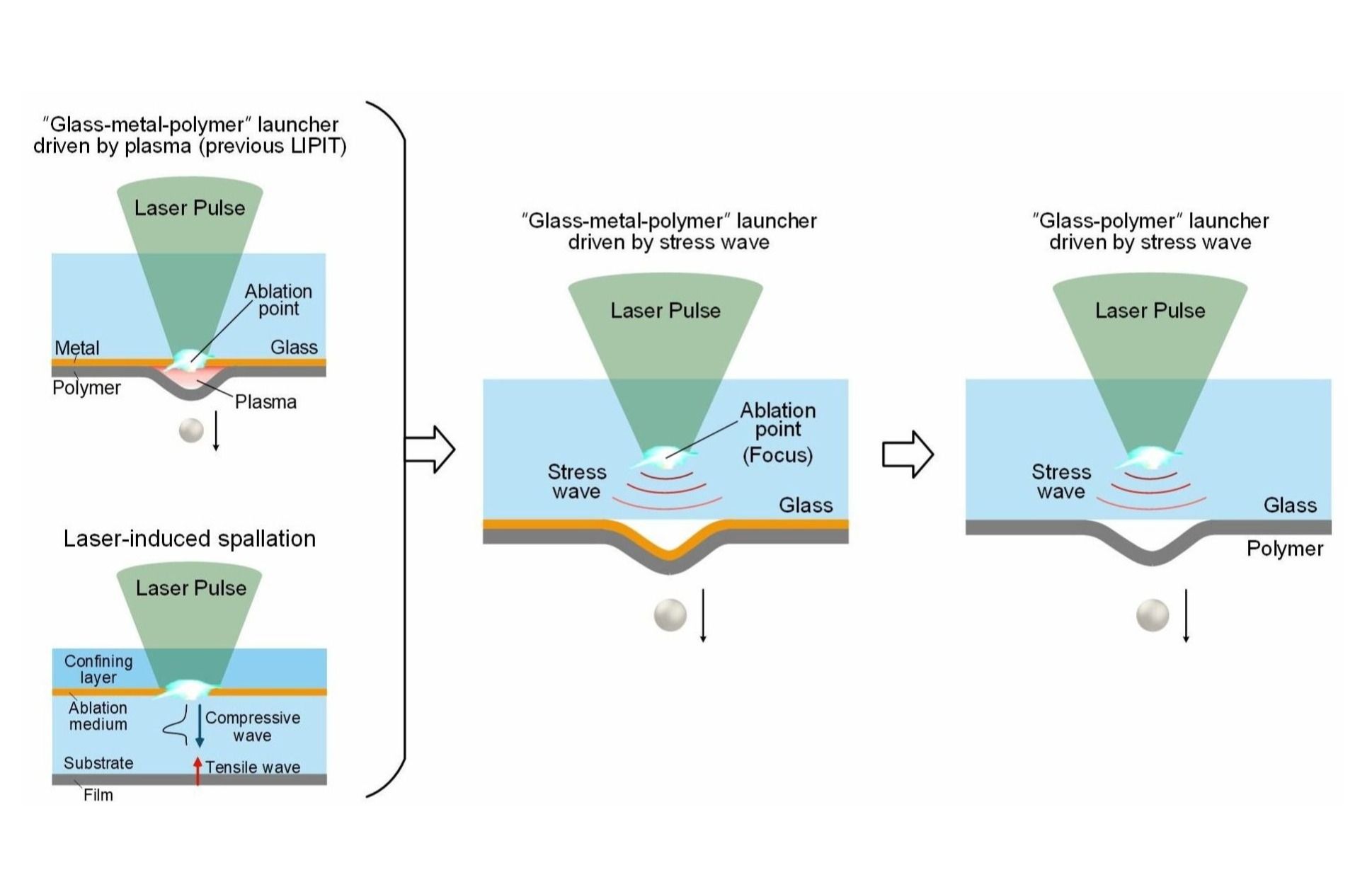

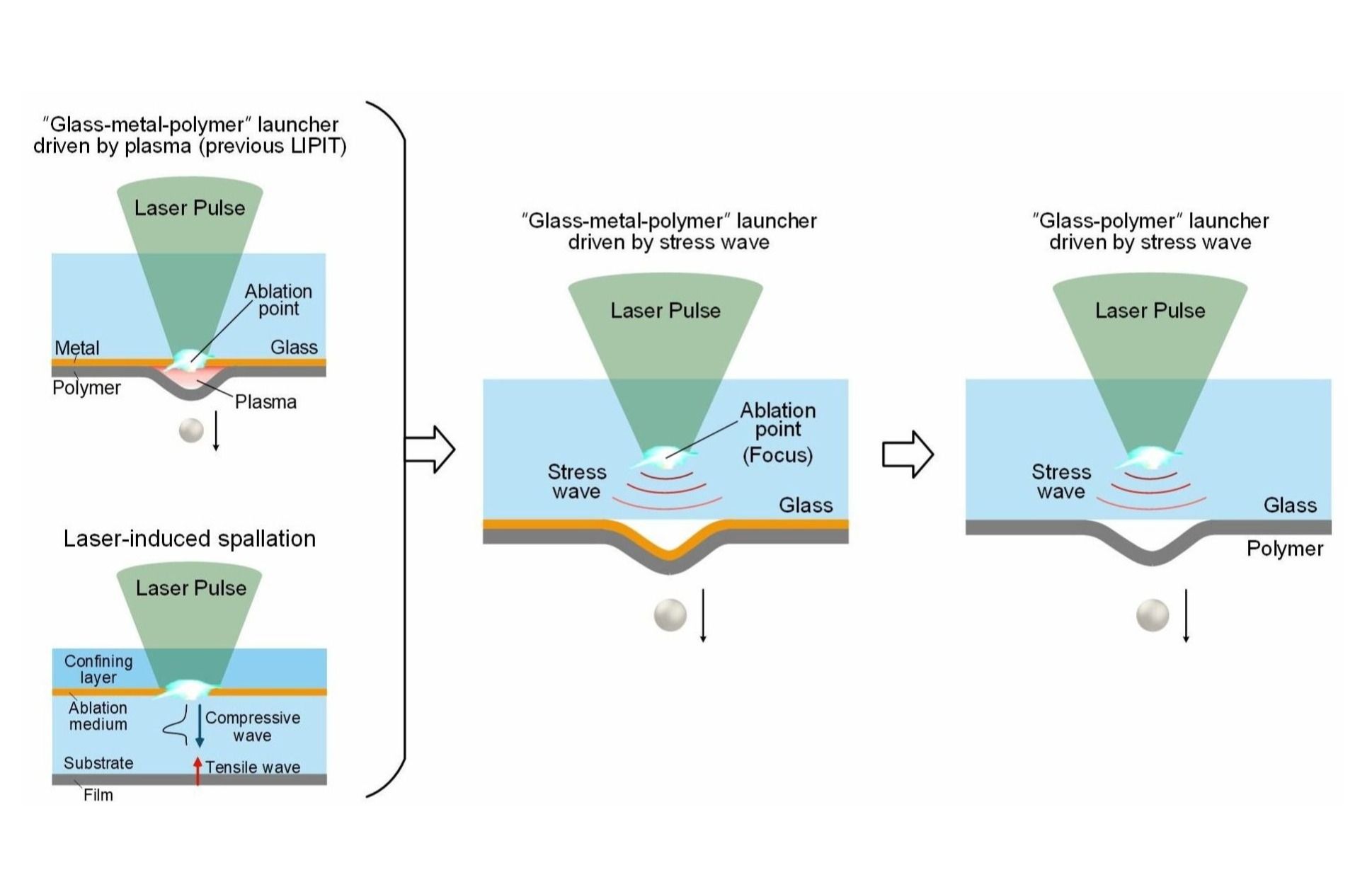

High-velocity projectile launcher of LIPIT: Utilizing stress wave driven by laser-induced glass breakdown

Ph.D. student Jiayu Chen proposed a novel method for launching projectiles by utilizing the stress wave driven by laser-induced glass breakdown, avoiding laser-plasma interference. The "glass-polyimide" launcher was developed for higher-velocity impact. The relationship between projectile velocities and laser/projectile variables was established and validated by experiments. This work was recently published in INT J IMPACT ENG