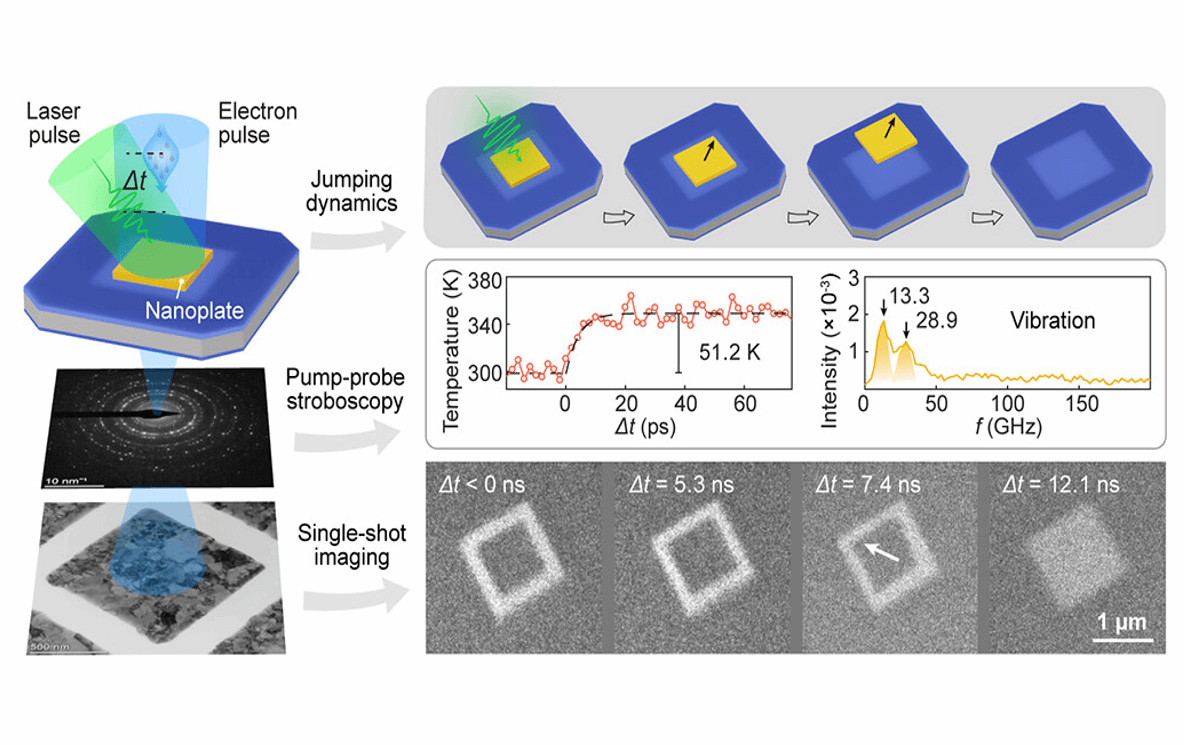

Thermal stress wave-driven regime in femtosecond laser-induced nanomaterial transfer revealed by ultrafast electron microscopy and atomic simulation

Dr. Zhou integrated pulsed lasers with TEM to observe nanoisland nanoscale transfer. Combining two-temperature modeling and molecular dynamics simulations, it revealed a novel thermal stress wave-driven transfer regime, with nanoislands detaching in tens of picoseconds and melting in nanoseconds—first confirmed by experiment and simulation. This work was recently published in INT J MACH TOOL MANU

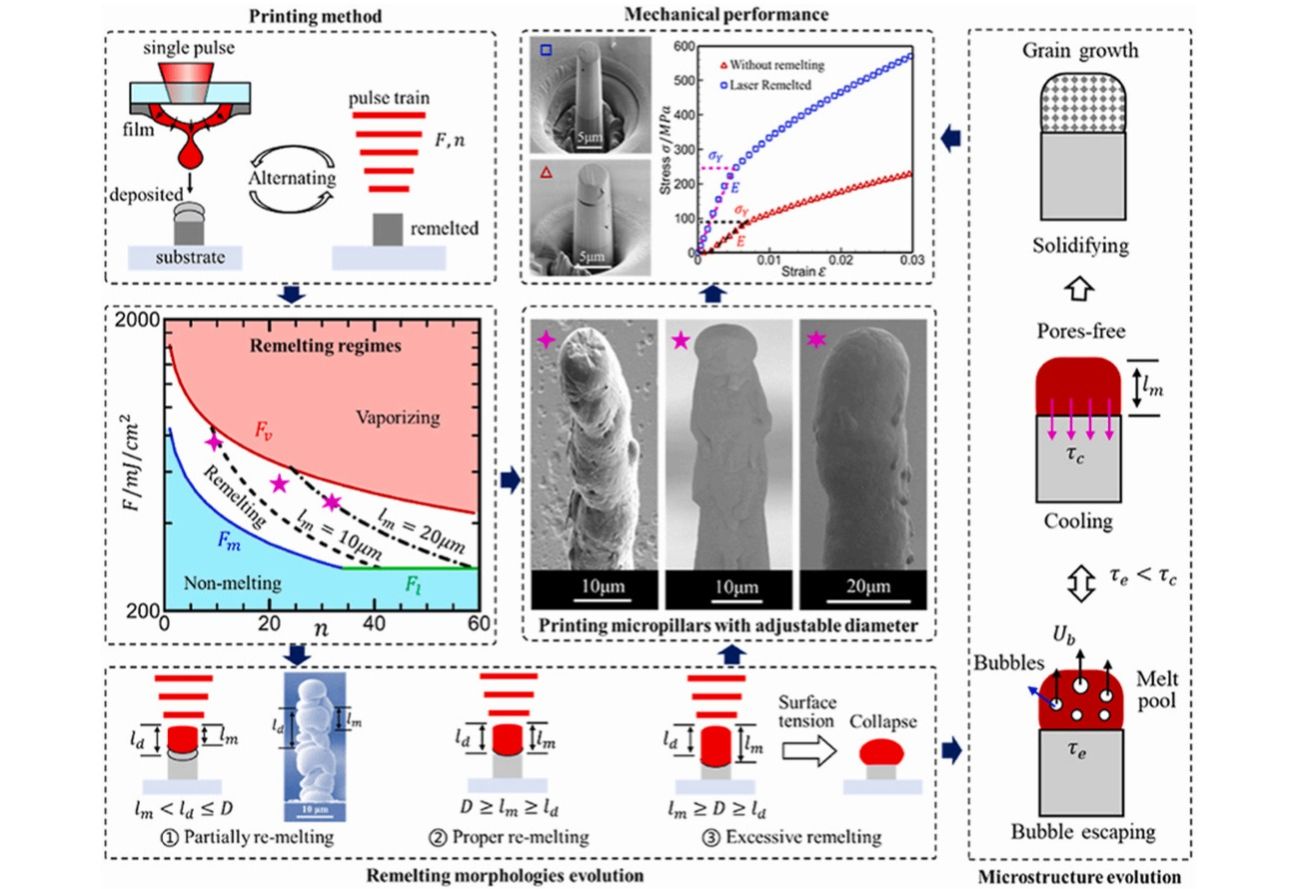

Spatiotemporal visualization of nanoscale rotational dynamics by movie-mode transmission electron microscopy

Dr. Zhou employed movie-mode transmission electron microscopy to investigate the rotational dynamics of laser-excited nanotriangles. It revealed axis-dependent rotation stability consistent with the tennis racket effect, validating classical rigid-body rotational theory at this scale, and quantifying nanotriangle-substrate adhesion to advance understanding of nanoscale rotational dynamics. This work was recently published in ACS NANO

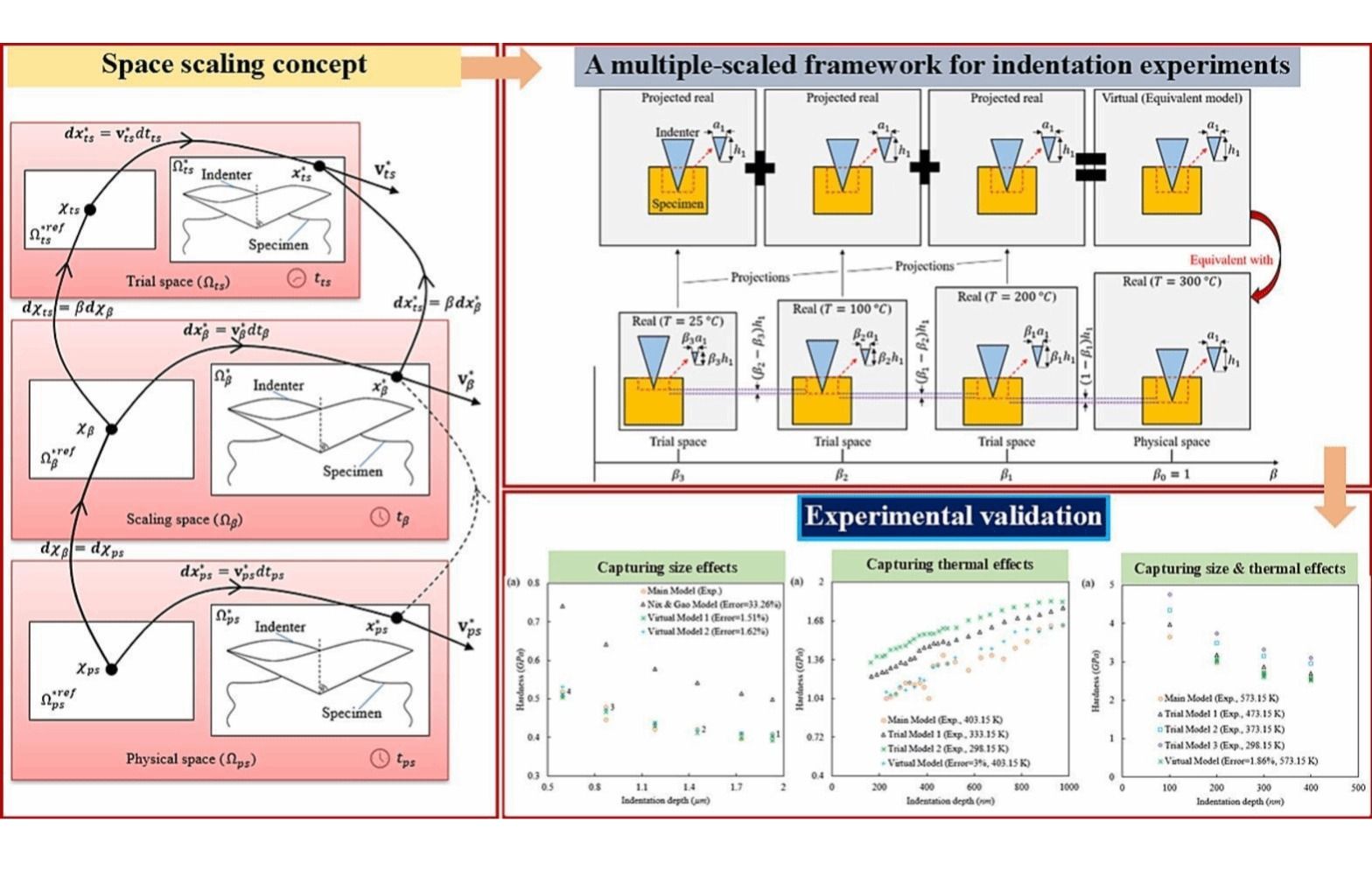

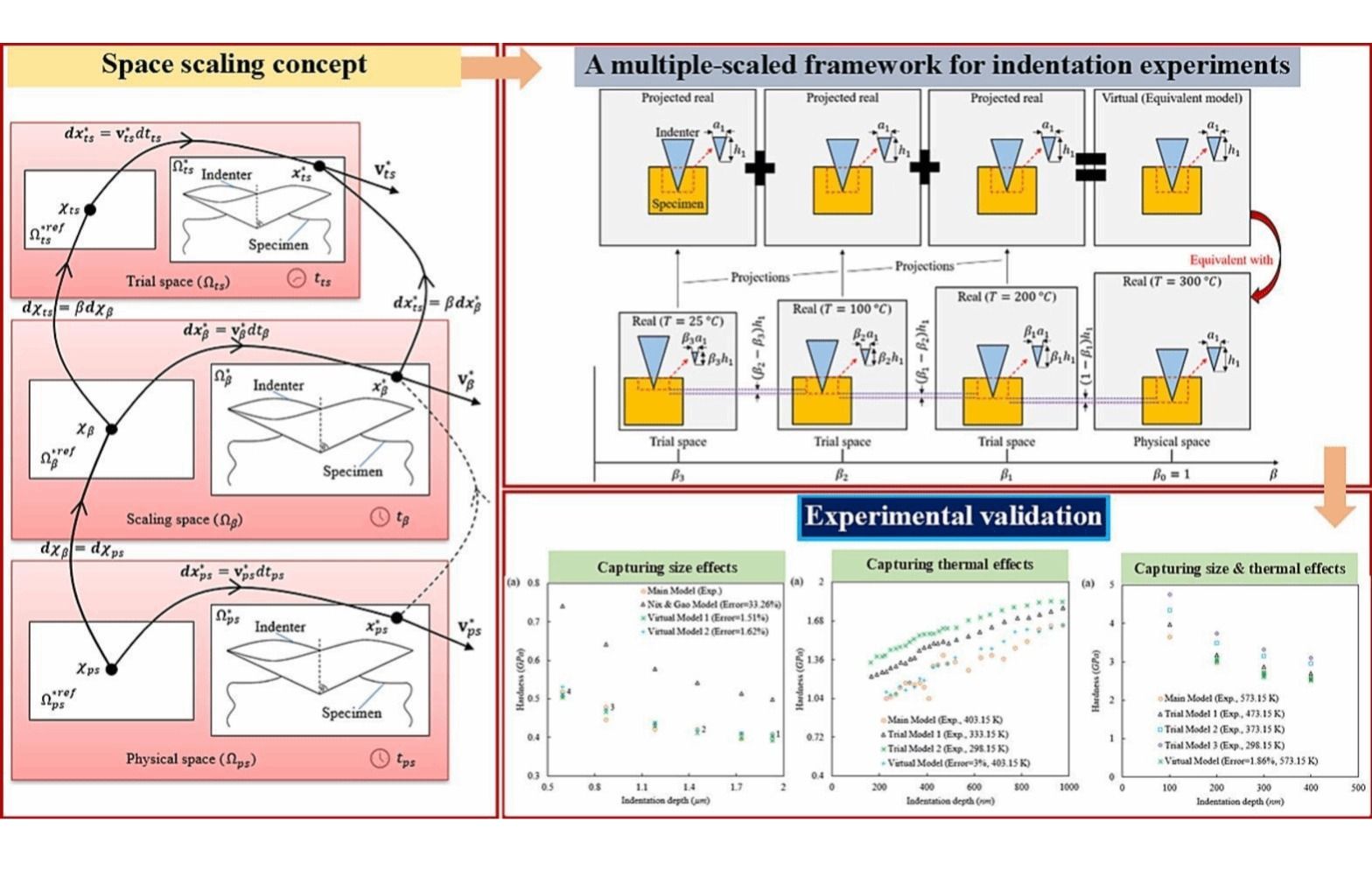

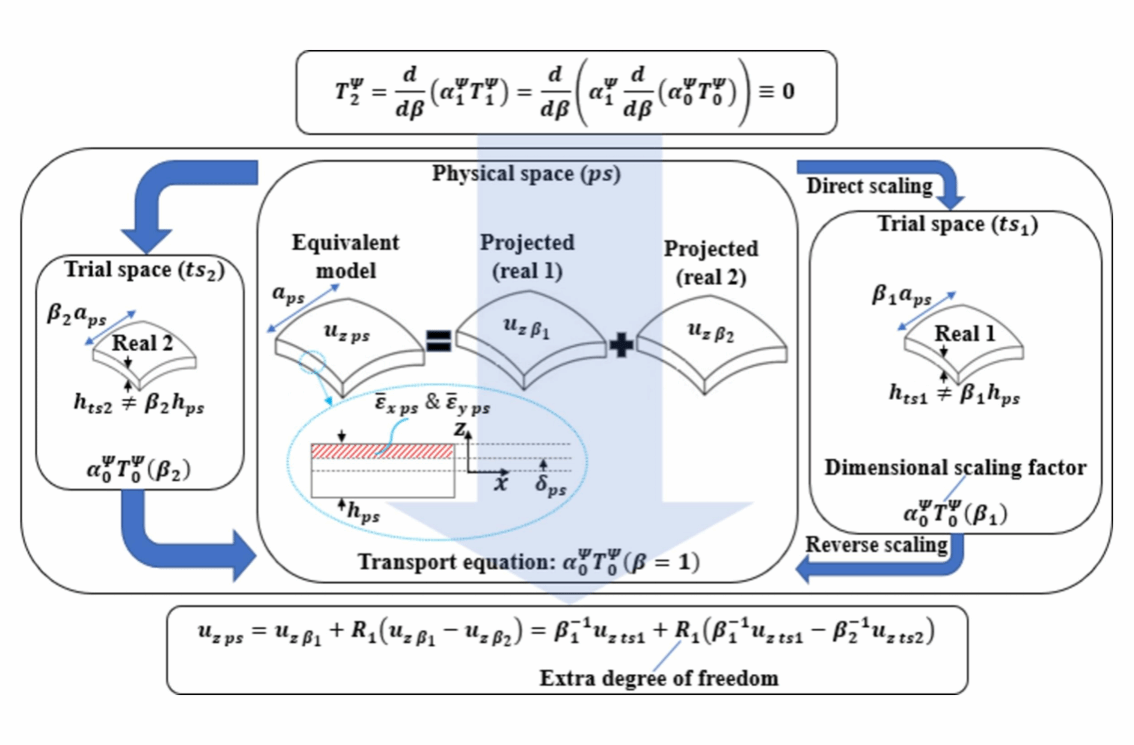

Indentation size effects: A study via finite similitude scaling theory

Dr. Hamed developed a multiscaled approach for indentation experiments using finite-similitude scaling theory. This methodology can capture indentation size effects and enable high-temperature analysis. Simulations and experiments showed that similitude correction can achieve high accuracy in hardness recovery for crystalline materials, with errors mostly under 9%. This work was recently published in MATER DESIGN.

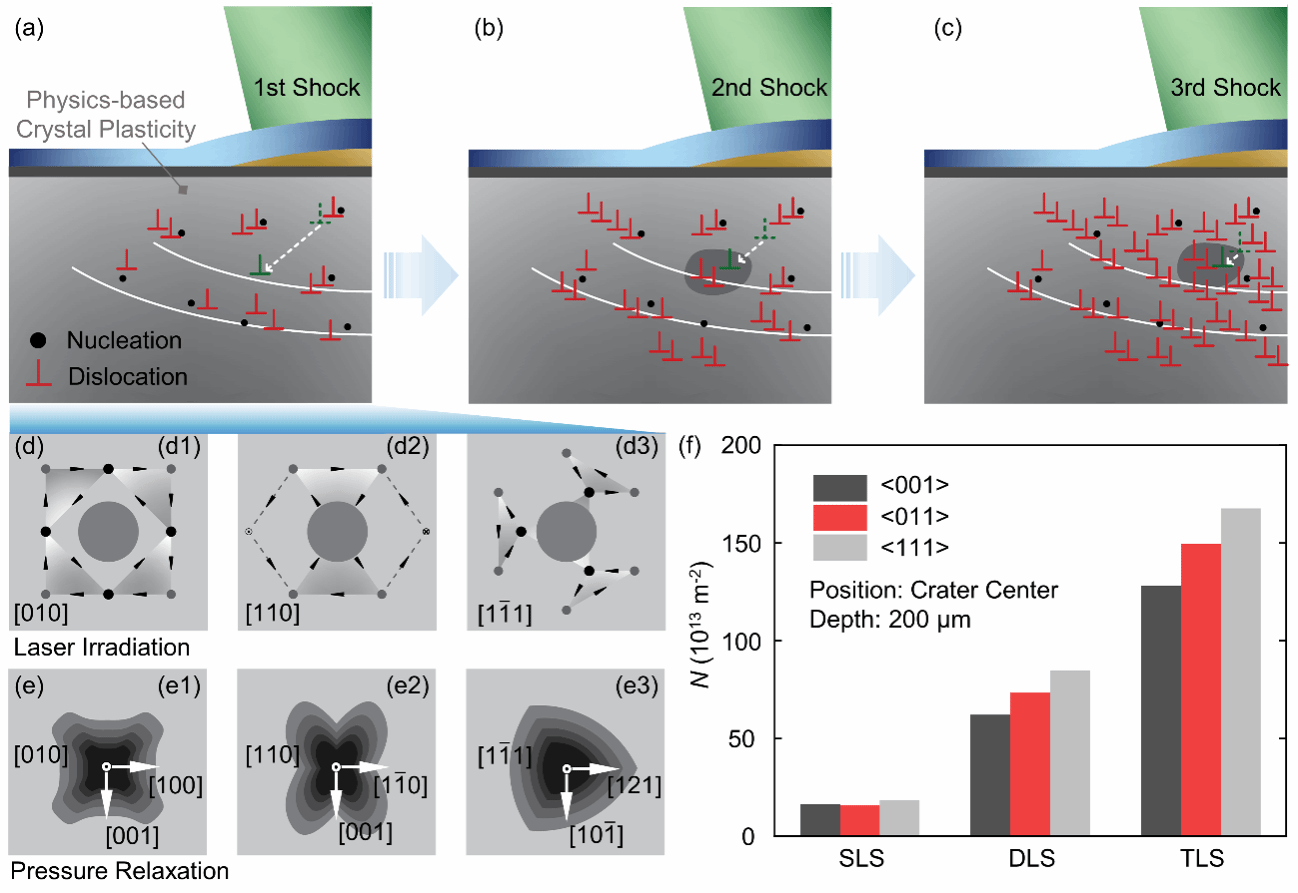

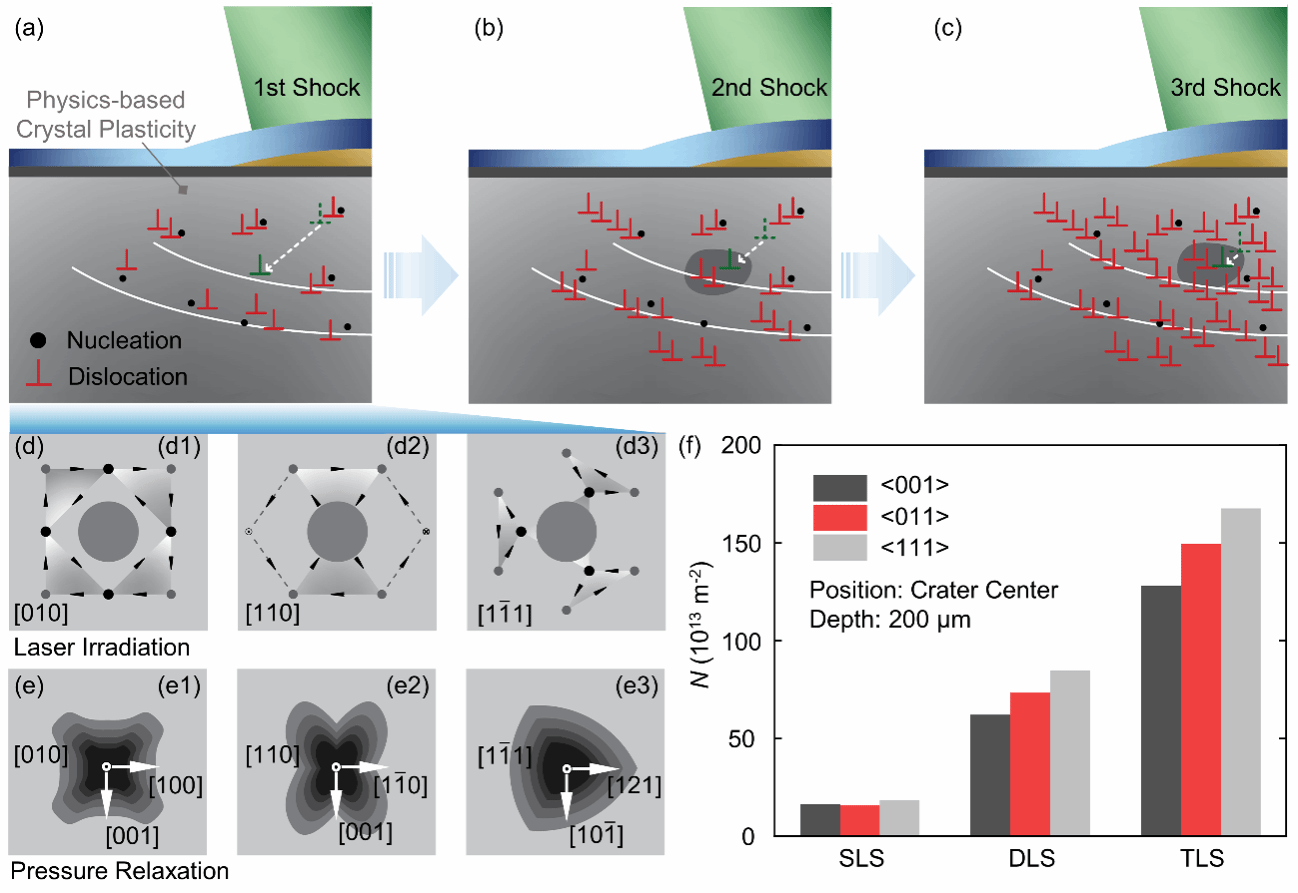

Dynamic dislocation response in aluminum single crystals under multiple laser peening: A physics-based crystal plasticity study

Ph.D. student Siyuan Chen simulated the dislocation response of aluminum single crystals under laser peening based on a crystal plasticity finite element (CPFE) model. The results indicate that dislocation patterns are axisymmetric during laser irradiation due to the ultra-high slip velocity. Phonon drag induced additional strength during the first shock for the low dislocation density. This work was recently published in INT J PLASTICITY

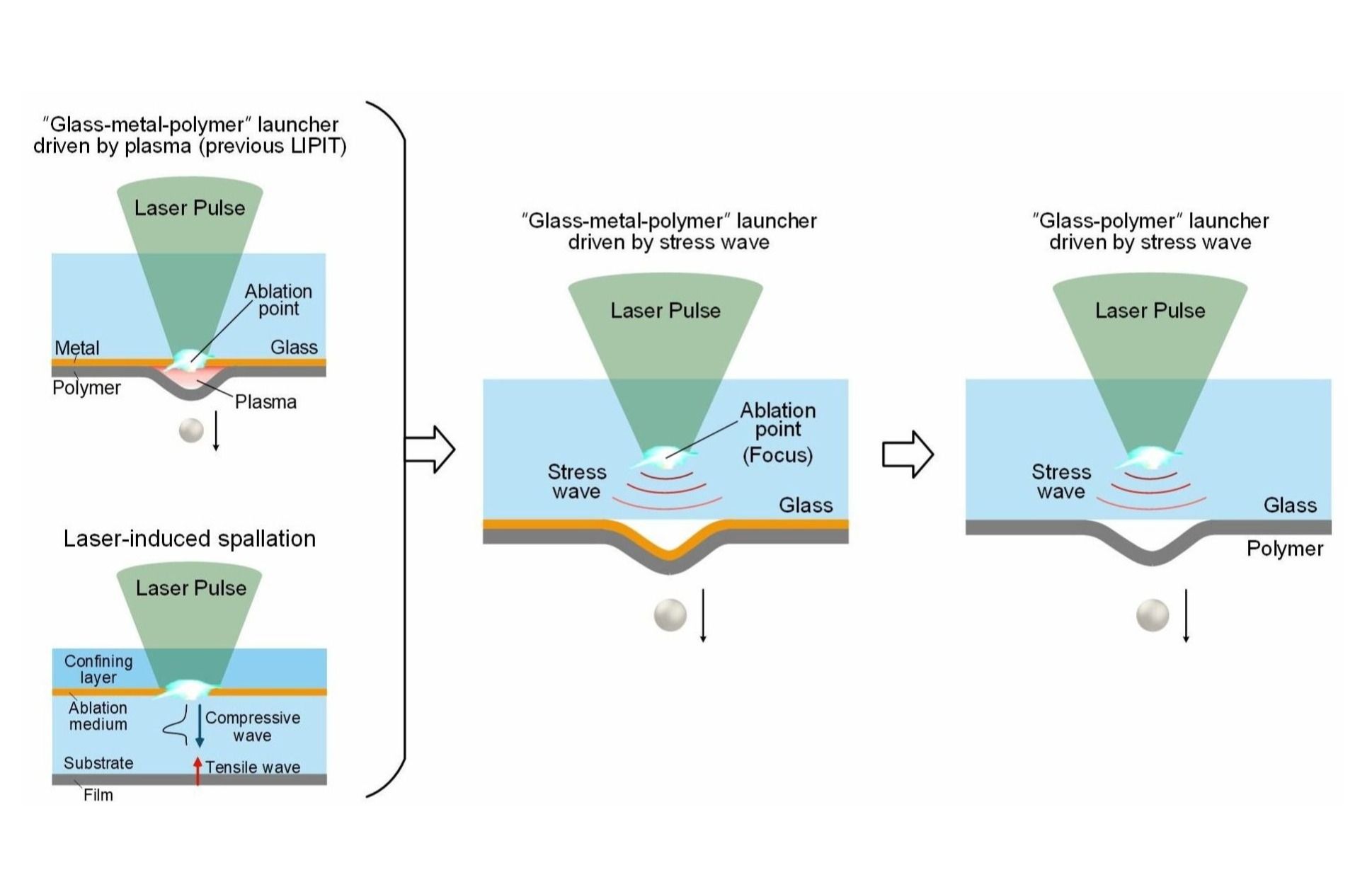

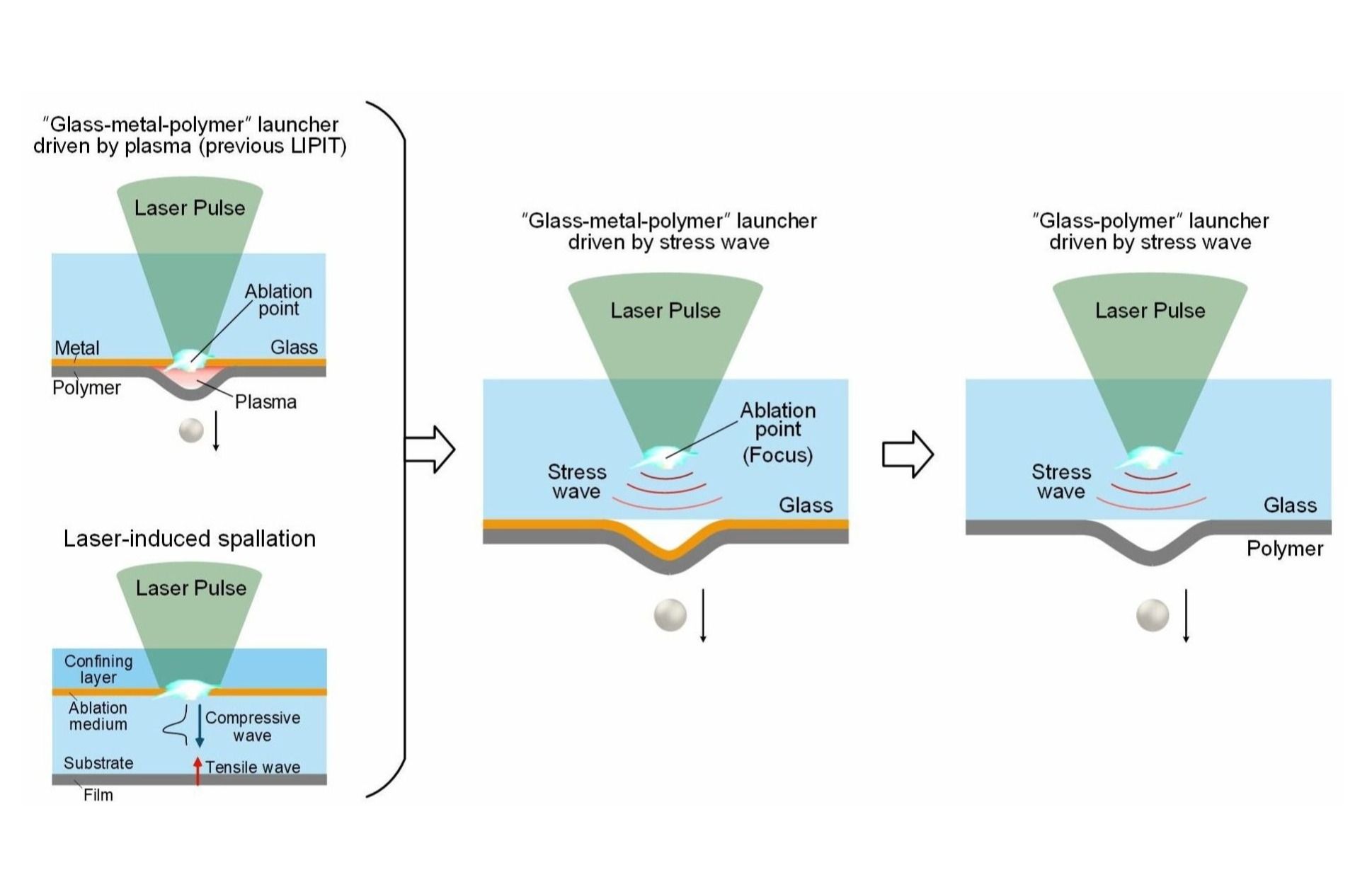

High-velocity projectile launcher of LIPIT: Utilizing stress wave driven by laser-induced glass breakdown

Ph.D. student Jiayu Chen proposed a novel method for launching projectiles by utilizing the stress wave driven by laser-induced glass breakdown, avoiding laser-plasma interference. The "glass-polyimide" launcher was developed for higher-velocity impact. The relationship between projectile velocities and laser/projectile variables was established and validated by experiments. This work was recently published in INT J IMPACT ENG

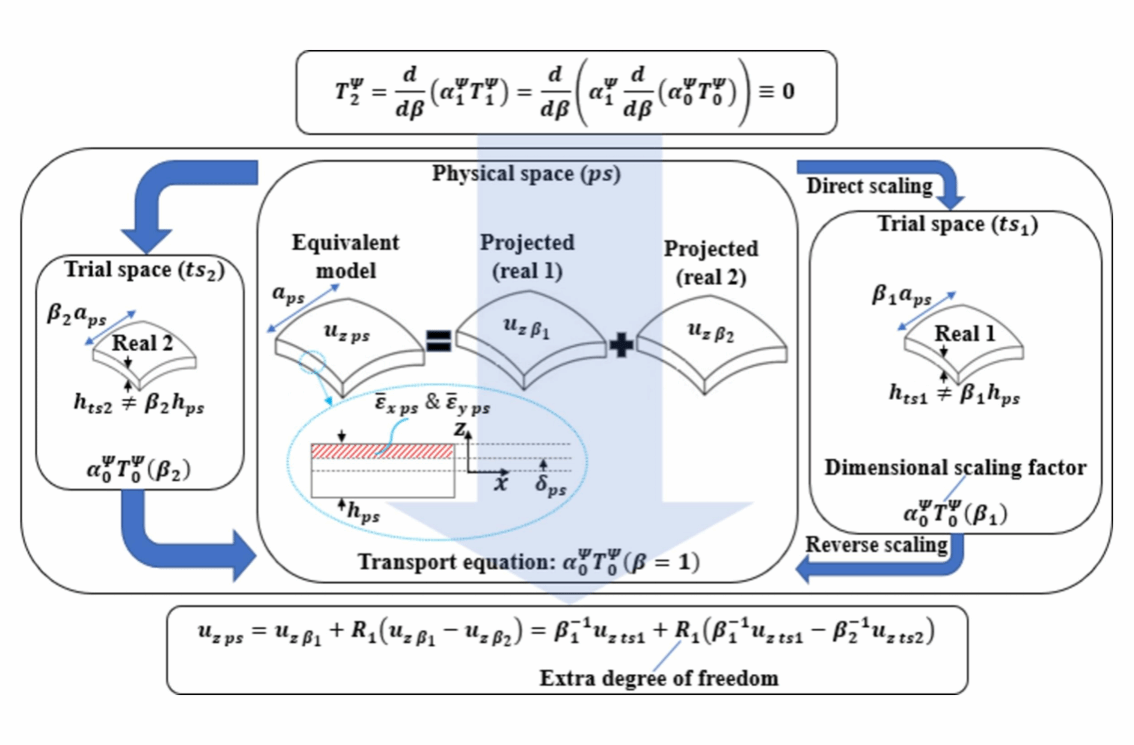

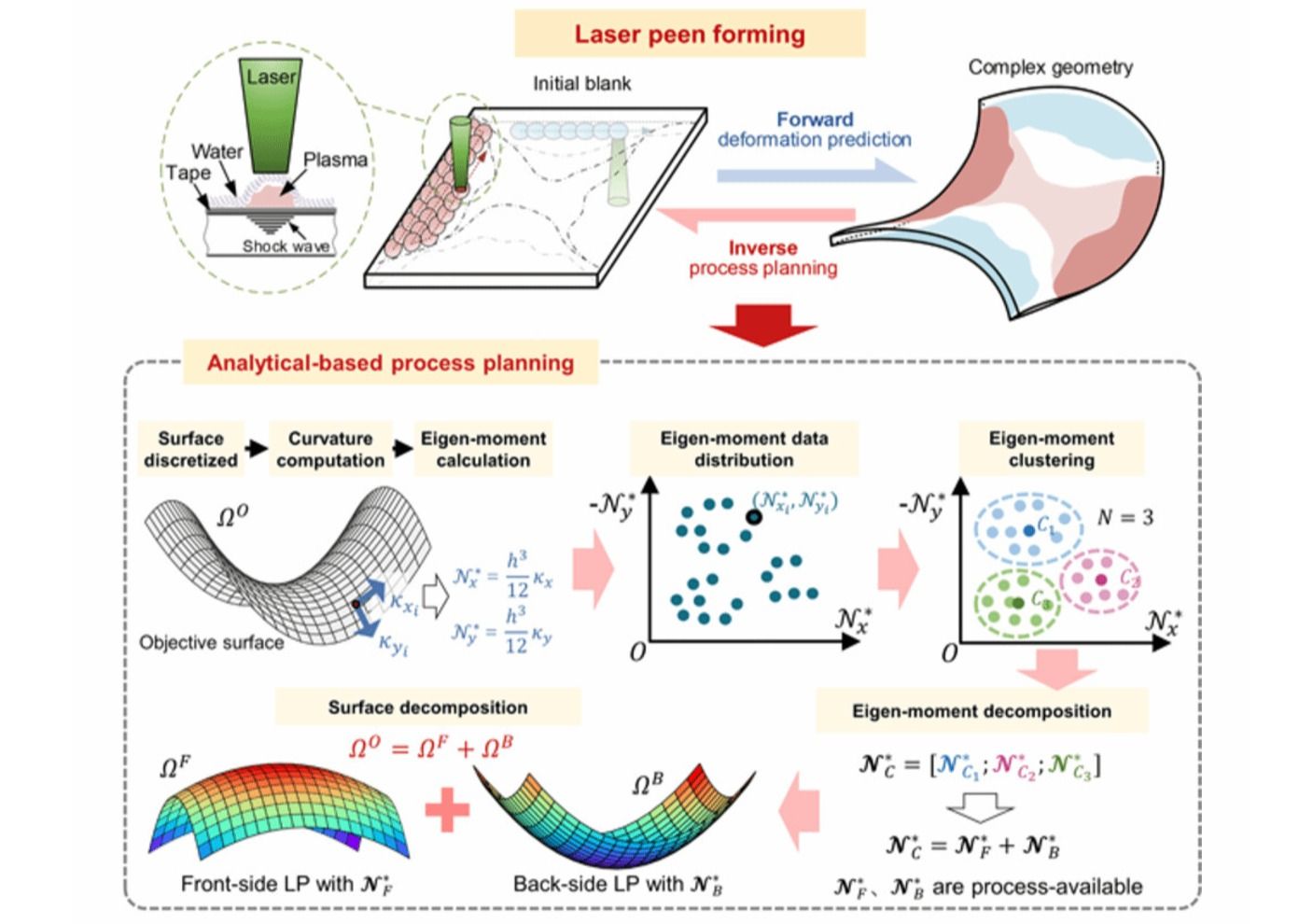

The scaling of laser peen forming: A two-experiment finite similitude approach

Dr. Hamed focused on the use of scaled experimentation for LPF to make experimental outcomes more broadly applicable to a wider range of process conditions. It is demonstrated in the work through experimental tests and simulation at two different scales, that geometric and loading similarities can be broken, yet the behavior of LPF can be quantified to good accuracy. This work was recently published in J MANUF PROCESS.